- English

- |

- Inquiry Cart

- |

- Sign In or Sign Up

DEFINITION

Activated carbon is a carbonaceous material characterized by a well developed pore structure and a very large internal surface area.

These characteristics provide activated carbon with a very strong adsorptive property.

PORE STRUCTURE OF ACTIVATED CARBON

a – micropores

b , f – mesopores (spherical and cilindrical)

c , e , d, – macropores (passing, internal, superfi cial)

RAW MATERIAL

Activated carbon is mainly produced from

– coal

– coconut shell

– wood

The yield of activated carbon is in the range between 15-35 % depending upon the raw material.

Generally coal gives high yield (30-35%) while coconut shell gives a lower yield (15-20%).

The approximate carbon content for different raw materials is shown in table 1.

Tab. 1 – Approximate carbon content of raw materials

Material | Carbon Content |

Coal | 65%-70% |

Coconut shell | 40%-45% |

Wood | 35%-40% |

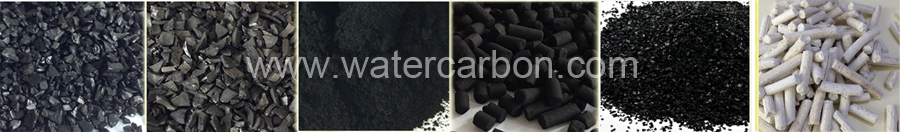

CLASSIFICATION OFACTIVATED CARBON

GRANULAR

Mainly used for water treatment (potable, urban and industrial waste water)

Different mesh size

Different starting material (coconut, mineral, vegetal)

EXTRUDED ( PELLET )

Mainly used for air treatment

Different diameter 2 – 3 – 4 mm (most common)

Generally mineral based

POWDER

Used for water treatment (drinking and waste)

Industrial process (wine industry, pharmaceutical, food industry)

Air treatment (incinerators)

Size: generally under 325 mesh

Different raw material (coal, coconut, vegetal)

CHARACTERIZATION OF ADSORPTION CAPACITY

The adsorption capacity of activated carbon is determined mostly by two factors.

INTERNAL SURFACE AREA

It is determined by mean of N2 adsorption and represent the surface area of the activated carbon and it is expressed in m2/g.

Internal surface area varies in the range 500-1800.

PORE SIZE DISTRIBUTION

Micropore: 0-20 A°

Mesopore: 20-50A°

Macropore: > 50 A°

Micropores and mesopores are supposed the be the most effective for the adsorption phenomenon and represent 80-90 % of the pore distribution.

Distribution of pores depends upon the starting material.

Coconut shell a.c. have a predominance of micropore (roughly 90%).

Coal based a.c. have a wide pore distribution (micropore/mesopore distribution is 60/30%).

Wood – peat based a.c. have high proportion of macropore (40-50%).

APPLICATIONS

l WATER TREATMENT

l GAS – AIR TREATMENT

l PERSONEL PROTECTION

l FOOD INDUSTRY

l CHEMICAL INDUSTRY

l PHARMACEUTICAL INDUSTRY

l CATALYSTS

PRODUCTS

1. Water Treatment

Type of Water | Process | Type of Carbon |

POTABLE WATER | Removal of organic compounds (pesticides, solvents…) Removal of organic compounds due to algae degradation/humic subs. | 1000, P900, 800, WP180 |

WASTE WATER Civil | Enhancement of Biological Process(I.B.T.)COD –BOD5 fi nal treatment | 1000, P900, 800, WP180 |

WASTE WATER Industrial Textile, Tannery, Food | Enhancement of Biological Process(I.B.T.)COD –BOD5 fi nal treatment, Color removal | 1000, P900, 800, WP180 |

2. Industrial Process

Type of Fields | Process | Type of Carbon |

ENOLOGICAL INDUSTRY | Wine decolorization | 1000, P900, 800,WP180 |

SUGAR, STARCH… | Decolorization | WP series |

FRUIT JUICE | Decolorization | WP series |

CITRIC ACID, TARTARIC ACID | Decolorization | WP series |

3. Air Treatment

INDUSTRIAL EMISSION | Process | Type of Carbon |

Automotive Industry | Solvents Recovery | S400 , S450 , SC450 |

Paint Production | Solvents Recovery | S400 , S450 , SC450 |

Printing, Adhesive tape | Solvents Recovery | S400 , S450 , SC450 |

Food industry | Odor removal | S400 |

Chemical, Petrochemical, Refinery | Hydrocarbons vapor, Sulfide removal Mercaptans | S400S, 470SPI-402, SSH-407 |

Incinerator (U.S.W.) | Dioxin, Mercury | P900P900S |

CIVIL EMISSION | Process | Type of Carbon |

Biological plants | Odor removal (Screening, Thickening, dehytration) | S400SPI-402 |

Sewage system | Pumping pits | S400SPI-402 |

For more details, please check www.watercarbon.com or send an e-mail to info@waterlandtech.com.

QQ: 380194832

Cell phone/Whatsapp: +86 13958074980

Skype: WL3572